Although the first light bulb prototype was seen in 1800 with Volta’s battery, the real light bulb was created three years later in 1802 by Davy. In 1879, Edison and Swan first developed the incandescent bulb that worked well. After tungsten, fluorescent lamps came in the 1930s and halogen bulbs were introduced in 1959. In the 1980s, CFLs became the first energy-saving bulbs and in 1994 white LEDs revolutionized lighting technology. After 2000, many people and businesses began to use LED lighting because of its good efficiency and durability.

Anyone who has ever wondered about the workings of an LED light bulb is in the right spot. Let’s tear open one of these cheap LED bulbs to find out the parts inside and find out what makes it function.

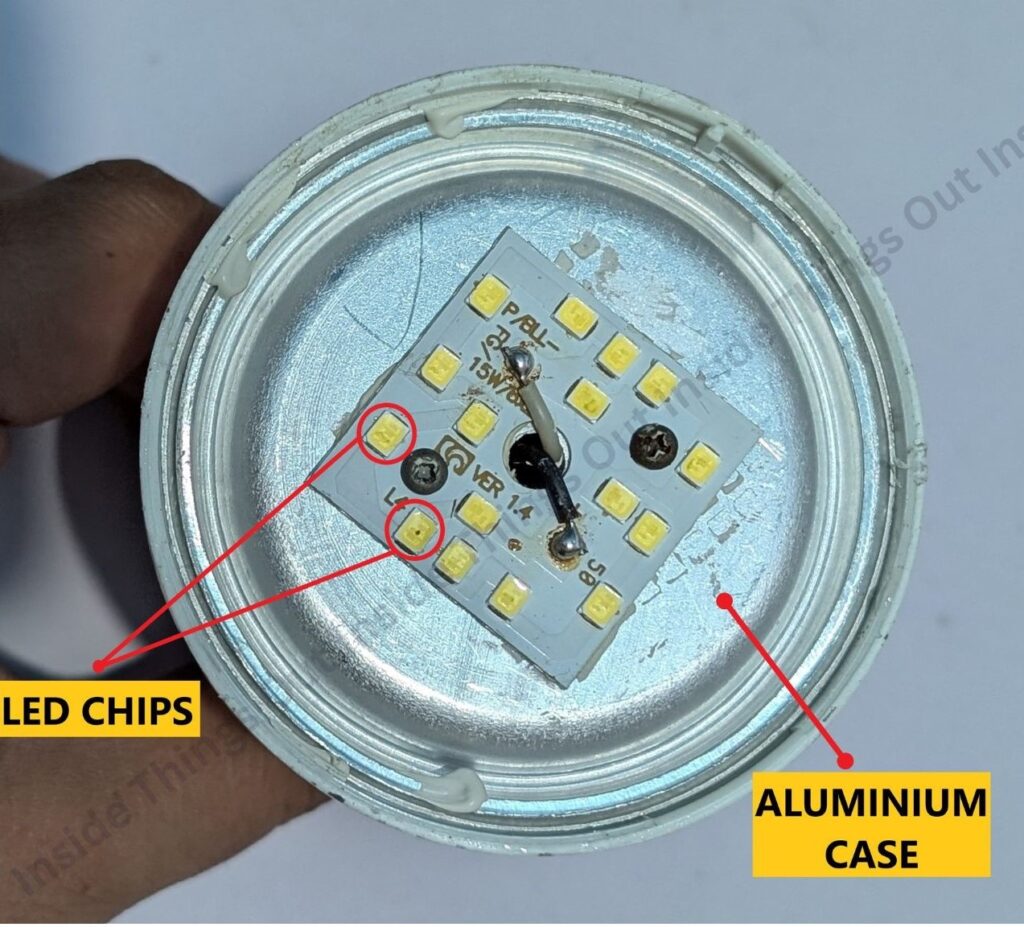

A) LED Chips

LED chips are what make LED lights emit light. They transform electricity into radiation we can see as light with the help of electroluminescence. The improvement in the LED—in terms of quality, efficiency, brightness and color—is mostly related to the type and arrangement of the chips.

Power per LED Chip

Total power = 15 watts

Number of LED chips = 16

Power per chip = 15 W ÷ 16 ≈ 0.9375 watts per chip

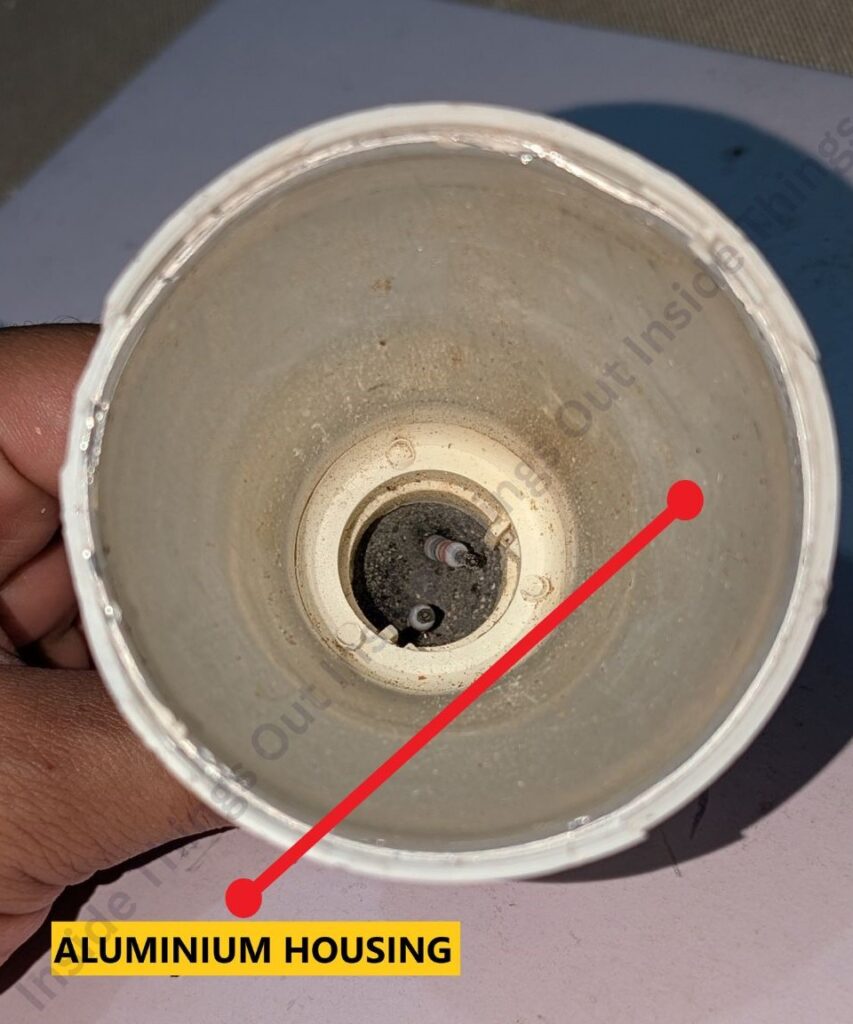

B) Heat Sink

This is a component, often made of aluminum that absorbs heat generated by the LED chips and dissipates it to the surroundings, preventing overheating.

C) Aluminium Housing

LED bulbs are often kept cool by the use of aluminium housing. Aluminium removes heat from the LED chip quickly which maintains the brightness, extends its life and avoids overheating. It is light, tough and provides efficient working in small designs.

D) Diffuser Cover

The diffuser cover made of plastic or glass, spreads light evenly, reduces glare, and protects the internal components of the LED bulb.

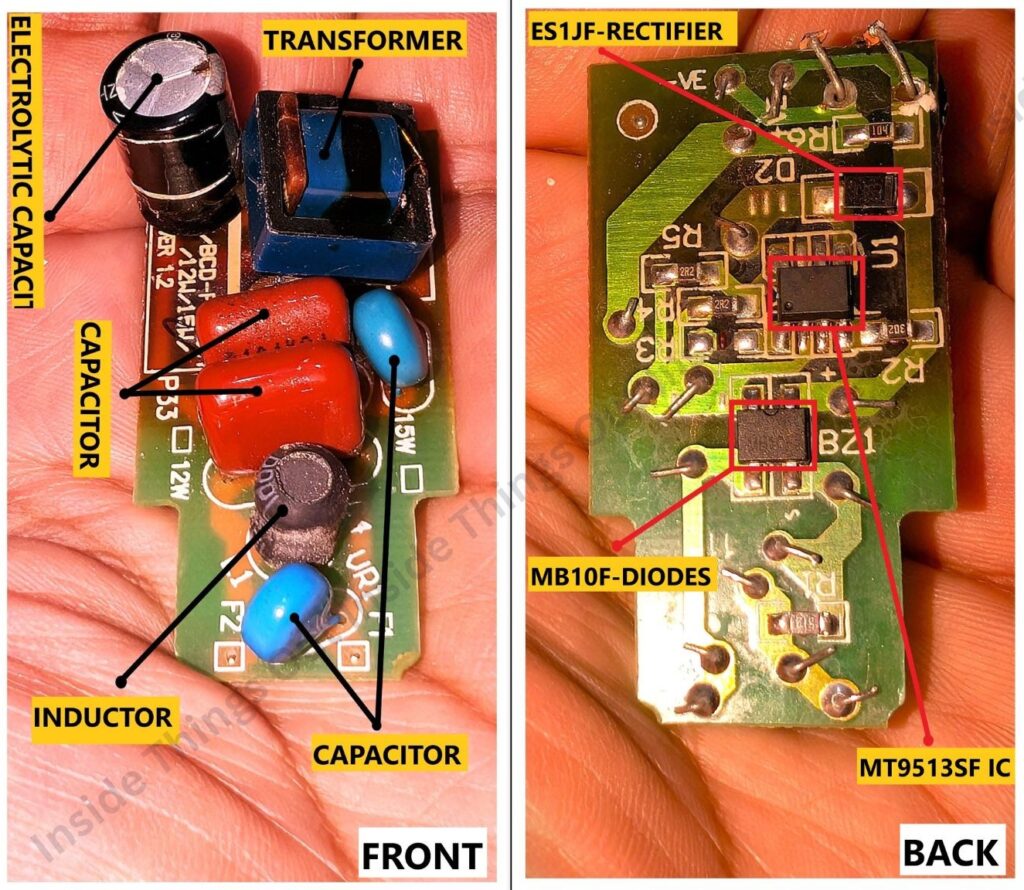

E) PCB Board:

The PCB board of an LED bulb consists of several essential components, listed below:

I) Transformer

An electrical transformer changes power from one circuit to another, keeping the frequency the same. Transformer allows the voltage to be either increased or decreased which also results in a corresponding change in current.

II) Electrolytic Capacitor

An electrolytic capacitor stands out because an electrolyte (a conducting material) allows it to deliver a higher capacitance than capacitors of the same size. Because it is polarized, the battery has both a positive (anode) and a negative (cathode) terminal, so it must be connected properly to a circuit.

Common Types:

a) Aluminum electrolytic capacitors: Most common, affordable, used in power supplies and audio circuits.

b) Tantalum electrolytic capacitors: Smaller, more stable, but more expensive and sensitive to over-voltage.

III) Capacitor

A capacitor is a passive two-terminal electronic component that stores energy in the electric field created between a pair of conductive plates separated by an insulating material called a dielectric.

IV) Inductor

An inductor is a passive electrical component that stores energy in a magnetic field when electric current flows through it. It typically consists of a coil of wire wound around a core (air, iron, or ferrite).

When current flows through the coil:

- A magnetic field is generated around it.

- If the current changes, the magnetic field changes, which induces a voltage (EMF) that opposes the change in current

V) MT9513SF IC

It is a high-PF, non-isolated, APFC, Buck IC for LED driver. It works in Quasi- Resonant Mode (QRM), which improves both of efficiency and EMI performance.

- Single-stage active power factor correction (PF > 0.90)

- Integrates ultra-high voltage power supply without external VDD capacitor and external power supply circuit

- High accurate LED current

- Good line and load regulation

Applications

- LED bulb, Spotlight

- LED tube

- Other LED lighting applications

VI) MB10F Diodes

This device features a glass passivated die construction, ensuring reliable and robust performance. Its miniature package design is space-efficient, making it ideal for use on densely populated PC boards. Optimized for surface-mount technology (SMT) manufacturing, it offers a low forward voltage drop, contributing to energy efficiency. The component is also environmentally friendly, featuring a lead-free finish in compliance with RoHS standards. Additionally, it is free from halogen and antimony, qualifying it as a “green” device.

Applications

Suitable for AC to DC bridge full wave rectification for SMPS, LED lighting, adapter, battery charger, home appliances, office equipment, and telecommunication applications.

VII) ESIJF-Rectifier

This device features a low-profile package designed for surface-mounted applications, making it ideal for compact electronic assemblies. It utilizes a glass-passivated chip junction, which enhances reliability and performance. Additionally, it offers a superfast reverse recovery time, improving efficiency in high-speed switching operations. The component is also lead-free and fully compliant with the EU RoHS 2011/65/EU directives, ensuring it meets environmental and safety standards.

Applications

Rectifier

In conclusion, since early experiments with electric light in the early 1800s, lighting has developed in impressive ways, ending up with today’s advanced LED bulbs. Today’s LED bulb is made from parts such as LED chips, heat sinks, housings and diffusers to help it give good light, use less energy and last a long time. The main board, known as the printed circuit board (PCB), uses capacitors, inductors, transformers, ICs and rectifiers to change electrical energy into bright and reliable light. When we learn about the function of an LED bulb, we realize how great lighting technology has gotten and continues to shape our future with less energy usage.

If you have any questions, or comments, or corrections, please let me know below.

Thanks for reading!