A booster pump, which is another name for the RO (Reverse Osmosis) motor, is a vital piece in today’s water purification systems. It helps create enough force to make sure the RO membrane cleans water in the required way. At first, industrial settings used RO systems in the 1950s and 60s, but small, energy-efficient diaphragm pumps made them possible for homes in the 1990s. By introducing brush-less motors and smarter controls, RO motors are less loud, stronger, and more efficient, which is essential for improving water quality in almost all areas.

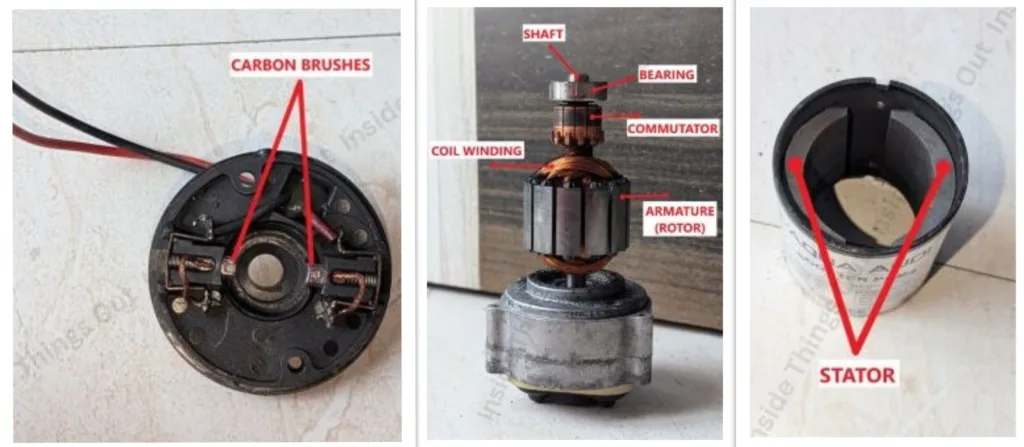

Components and Their Functions:

Electric Motor Section

1) Copper Coil Winding:

A solenoid is a set of copper wires insulated by plastic, tightly put around an iron core. When we supply electricity to the coil, it makes a magnetic field appear.

2) Rotor (Armature):

This element inside the motor makes it move. The coil is put inside the stator’s magnetic field and starts to rotate as electric current flows, transferring its energy to the pump.

3) Carbon Brushes:

The electrical link between the rotating rotor and the power supply is kept by carbon brushes in brushed motors.

4) Bearings or Bushings:

These round and smooth bearings make the rotor shaft spin easily during operation and help the motor last a long time.

5) Commutator:

Wrapped around the motor shaft, a commutator acts as a split ring and changes the direction of current in the motor every time it turns, so the rotor rotates unidirectionally while carbon brushes keep power flowing to the motor winding.

6) Stator:

By using permanent magnets or electromagnets, the stator makes a magnetic field and connects to the rotor involved in creating the motion.

Pump Head Section

1) Pump Housing (Body):

The main housing on the pump is made of stainless steel or plastic, to surround all the components and prevent them from water coming in.

2) Diaphragm (in diaphragm-type pumps):

Due to the motor, the flexible membrane moves back and forth, making a pressure difference that attracts water to the inside and pushes it out. Pressure and suction in the pump are made by a cylindrical plunger that forces water through it.

3) Inlet & Outlet Valves:

Check valves let the water on the side of higher pressure enter and leave the other side, thus preventing backflow.

4) Pressure Chamber:

Inside the pump head is a small chamber that assists in raising the water’s pressure before it reaches the membrane.

5) Gaskets & Seals:

A rubber gasket or synthetic ring is there to stop water from escaping and keep the pump’s pressure up.

How it works:-

- Electricity powers the motor coil, generating an electromagnetic field.

- The magnetic field causes the rotor shaft to spin, converting electrical energy into mechanical motion.

- The rotating shaft drives a diaphragm or piston, creating alternating suction and compression cycles.

- During the suction stroke, water enters through the inlet valve into the pump chamber.

- On the compression stroke, the diaphragm or piston pushes water under pressure toward the outlet valve.

- Pressurized water exits the pump, flowing toward the RO membrane or filtration system.

- Seals and gaskets prevent leaks, while one-way valves ensure consistent, unidirectional water flow.

In conclusion, generating the sufficient pressure for reverse osmosis is possible only because of the help of an RO motor (booster pump) in water purifiers. There are two major parts: the electric motor generates movement and the pump head makes the water more forceful by using that movement. The pump works smoothly and pumps water at high pressure in just one direction because of the coil, rotor, diaphragm, and seals. Pressure helps membrane filtration do its job well, and that results in pure and clean water.

If you have any questions, or comments, or corrections, please let me know below.

Thanks for reading!