When you open the hood of your car you get greeted with a world of engineering ingeniousness meant to drive you on the road- this is the world of the engine. The engine of a car commonly referred to as the heart of the vehicle is a very complicated system that translates power to movement. In the case of a small-sized hatchback or a technically advanced sports vehicle, the engine will have a balanced system of internal components, which are solely expected to provide performance, efficiency, and reliability.

Through this detail article, we will examine the primary parts of a car engine, their role in the engine and the car in general and how they all come together to work together.

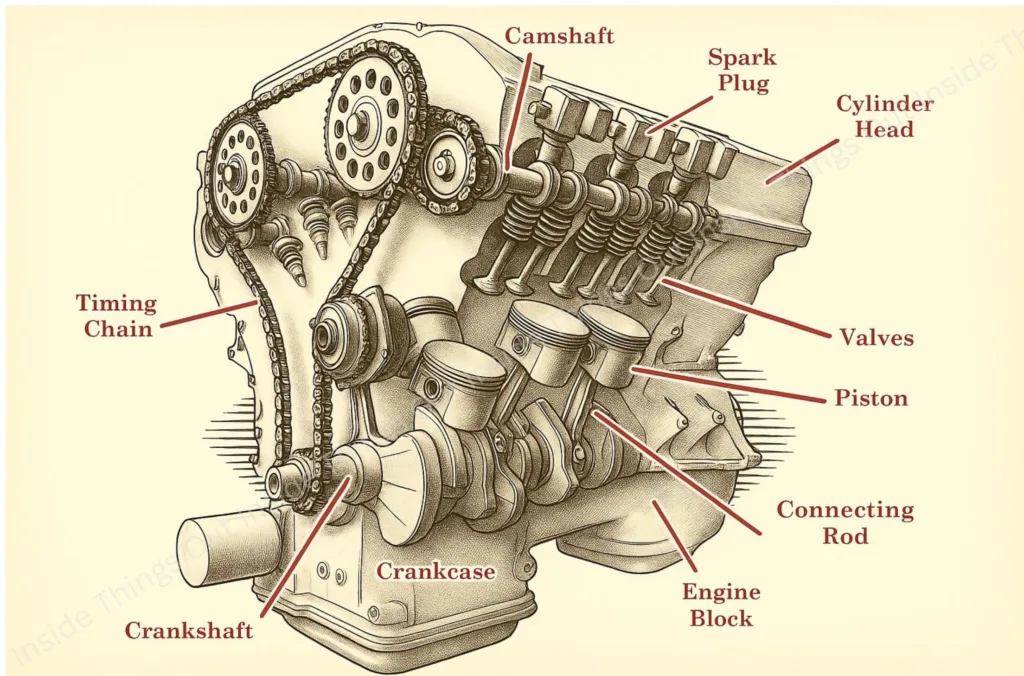

1. Cylinder Block: The Engine’s Foundation

The engine block (or the cylinder block) is the latter structure of the engine. This huge metal frame is usually constructed of cast iron or aluminium alloy and contains various parts that are fully part of the engine such as the cylinders, the pistons, and the crankshaft. It is actually made with internal coolant and oil passageways through which the coolant and oil should flow through in order to cool the engine and lubricate it. It may have:

- In line arrangement: cylinders in a straight position.

- V-type layout: This is where the cylinders take the shape of a V.

- Flat/Boxer layout: cylinders are flat and facing opposite one another.

It is the cylinder block that preconditions the process of the combustion and houses most of the engine moving elements.

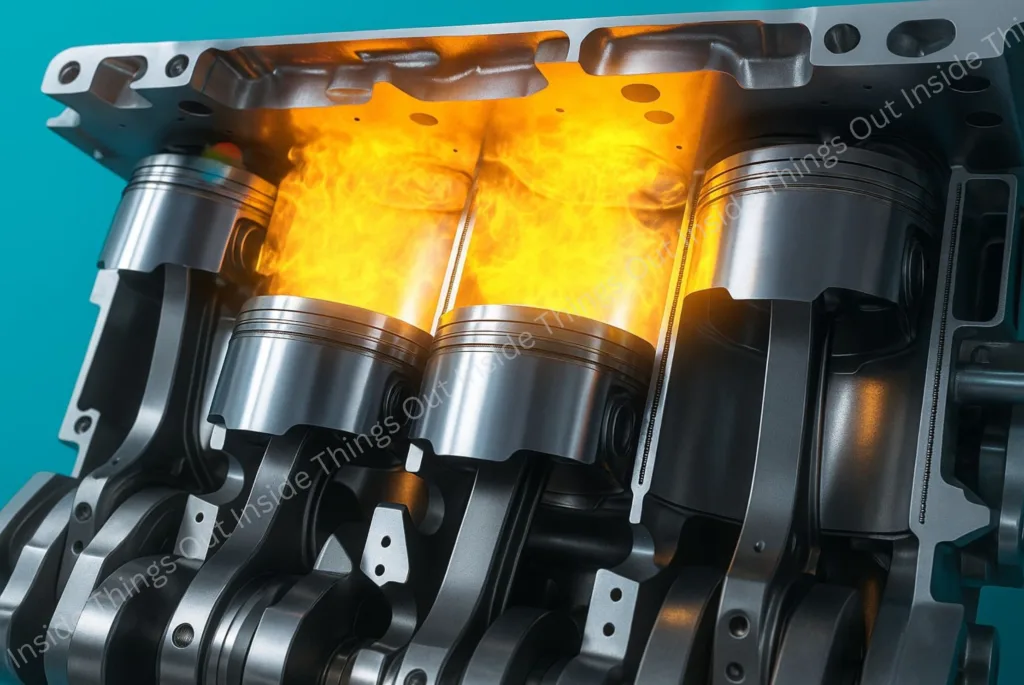

2. Cylinders and Pistons: Power Generators

The cylinder block contains one or more cylinders in which there is a piston sliding up and down. This movement is achieved through burning of fuel. Pistons: these are made of aluminium alloy with the capability of withstanding pressure and high heat. They are perfectly fitted in the cylinders and they have piston rings that will assist the compression and against oil and gas seepage.

This fundamental move within a cylinder trails a four-stroke procedure:

1. Intake stroke Air-fuel mixture is admitted to the cylinder.

2. Compression Stroke – the mixture is also compressed by the piston.

3. Power Stroke– A mixture is ignited and compressed by a spark generating pressure to the piston.

4. Exhaust Stroke– Gases being exhausted are burned off.

It is called the four-stroke cycle and it is the foundation of the majority of modern internal combustion engines.

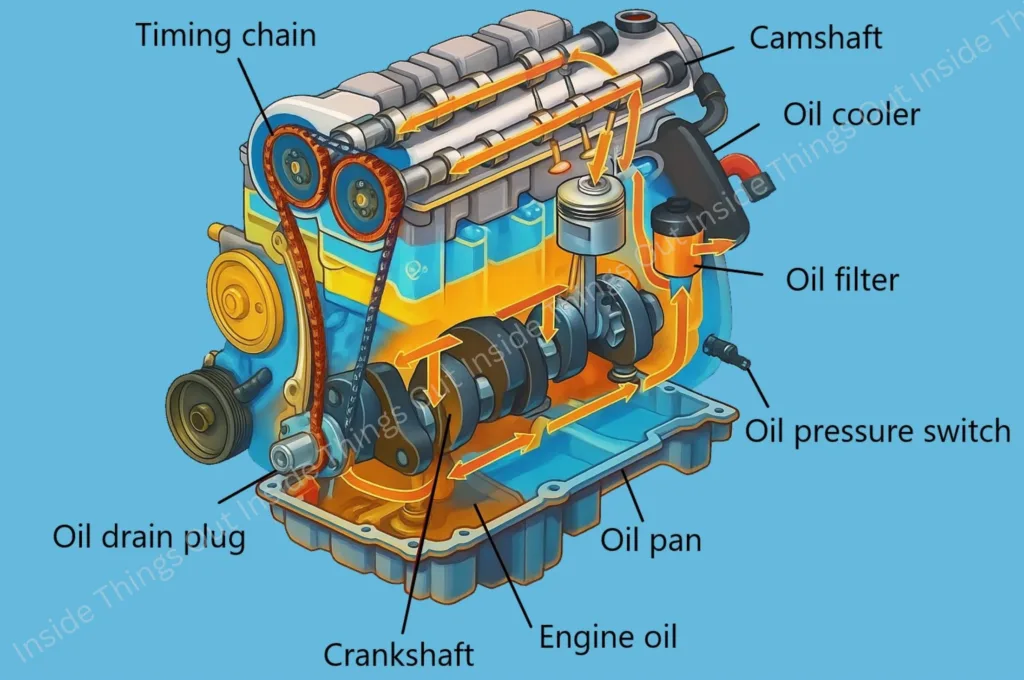

3. Crankshaft: Converting Motion

The crankshaft is at the base of cylinder block, which is connected to pistons via connecting rods. The pistons swinging up and down are changed to rotary motion by the crank shaft. It is this twisting that ends up propelling the wheels of your vehicle.

Crankshaft is to be perfectly balanced so as to prevent vibrations and smooth running of the engine. It is supported by bearings, and they also minimize friction when rotating.

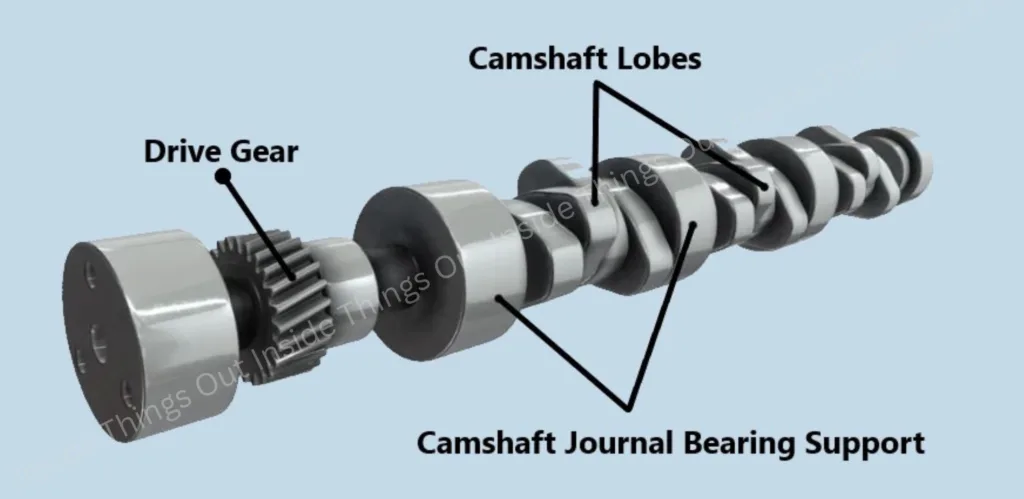

4. Camshaft: Timing is Everything

The timing of opening and closing intake and exhaust valves is achieved with the help of camshaft. Its lobes (cams) are specially fashioned so that they push on valves, permitting fuel and air in and outdoors on the exact instances that exhaust is to be released.

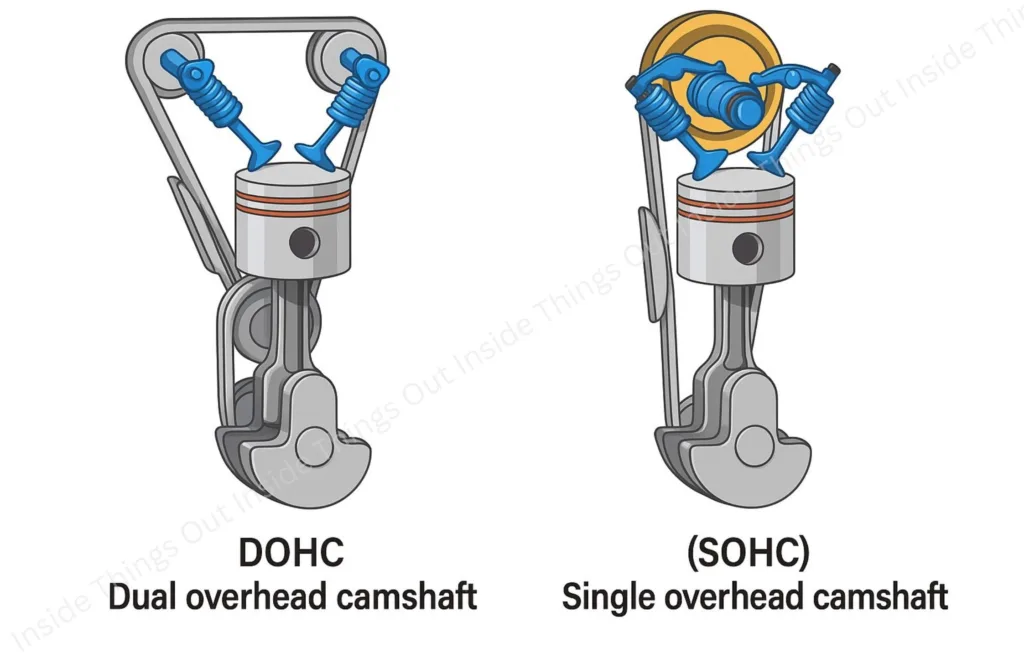

There is a possibility of having one or more camshafts in engines:

- Single Overhead Camshaft (SOHC) – There is a single overhead cam that is shared by the valves.

- Double Overhead Camshaft (DOHC) -2 cam shafts with one open ing and one out putting valves.

The camshaft is generally linked to the crankshaft through the timing belt, chain or gears and by so doing this provides synchronization.

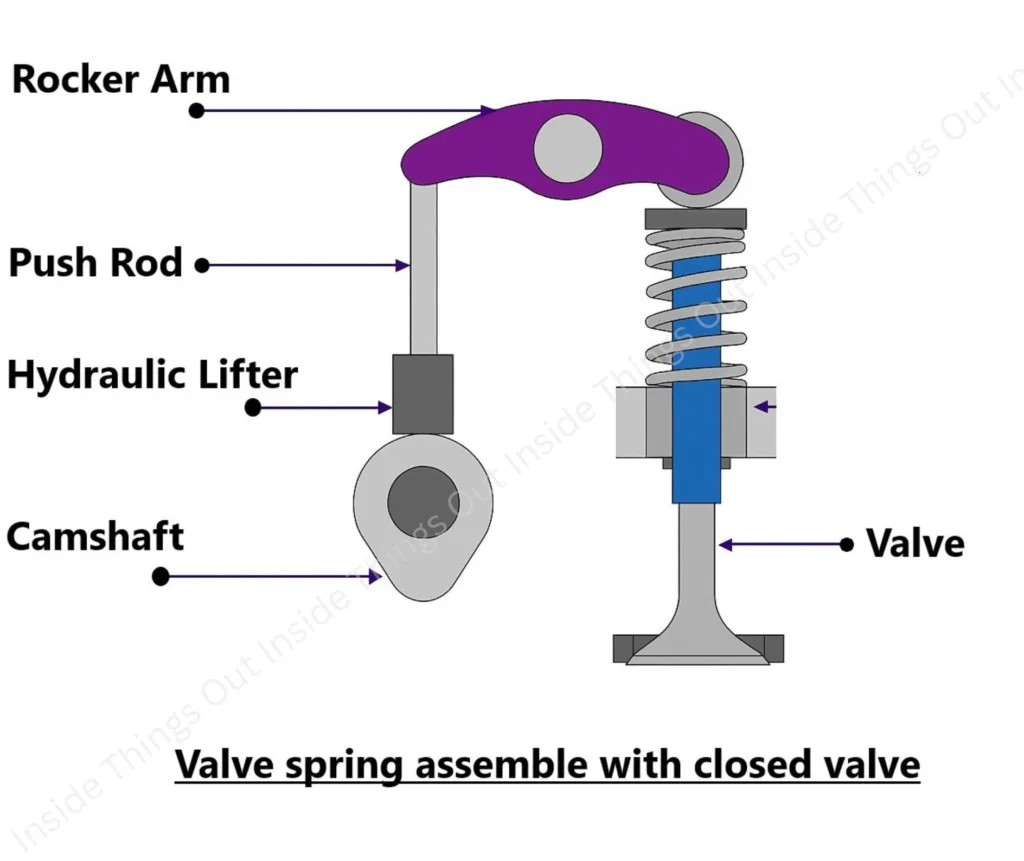

5. Valves and Valve Train

Each cylinder contains:

- Intake valves- Allow air fuel mixture into the engine.

- Exhaust valves- Let out burnt gases.

The camshaft controls these valves thru the use of such components as:

- Pushrods

- Rocker arms

- Hydraulic lifters

It is important to note that the accurate action of these valves makes sure that the engine is breathing therefore being efficient.

6. Timing Belt or Chain

The timing belt (or timing chain in certain engines) causes the rotation of the crankshaft and the camshaft to move in alliance. This makes the valves open and close in the same time as the movement of the piston. When it is inappropriate within the time, then it may cause poor performance or devastating destruction of the engine.

Timing belts are less noisy and lighter ones that require frequent replacement. Timing chains are more lasting, however heavier and more noisy.

7. Combustion Chamber

This is where the magic is performed in the combustion chamber. The cylinder head, piston top, and cylinder form a surrounding space, the explosion of the air-fuel mixture occurs. This causes a corresponding force which pushes the piston to move downwards and hence a resultant power.

New engines are built so that their combustion chamber creates a better mixture of fuel and air that allows more efficient combustion and fewer emissions.

8. Spark Plugs

Spark plugs make the air-fuel mixture to combust in petrol engines. They produce a high-voltage electric spark, at the optimum moment. Faulty spark plug may result in misfires, uneconomical using of the fuel and trouble in starting up the engine.

Diesel engines however are high compression engines and they require glow plugs to facilitate cold starts.

9. Fuel System: Injectors and Carburetors

Newer engines take up fuel injectors to feed fuel straight to the combustion chamber or the intake manifold in a precise and fine manner. These are computer controlled to make them achieve maximum fuel efficiency and emissions.

The older ones have a carburetor mixing the air and fuel and then allows it to reach the engine. Carburetors are less efficient and less common although they are simpler.

Other things in the fuel system are:

- Fuel pump- It transports fuel in the tank to the engine.

- Fuel filter- A cleansing filter against the remnants and contaminants.

10. Oil System and Oil Pan

Friction creates heat and wears. This is where lubrication system comes to the rescue.

It diverts oil to all the moving parts of the engine:

- Oil pan– It is the reservoir used in oil.

- Oil pump- Delivers oil to the whole engine.

- Oil filter- Filters out the dirt and metal pieces.

Oil decreases wear, dampens overheating and cleanses the engine.

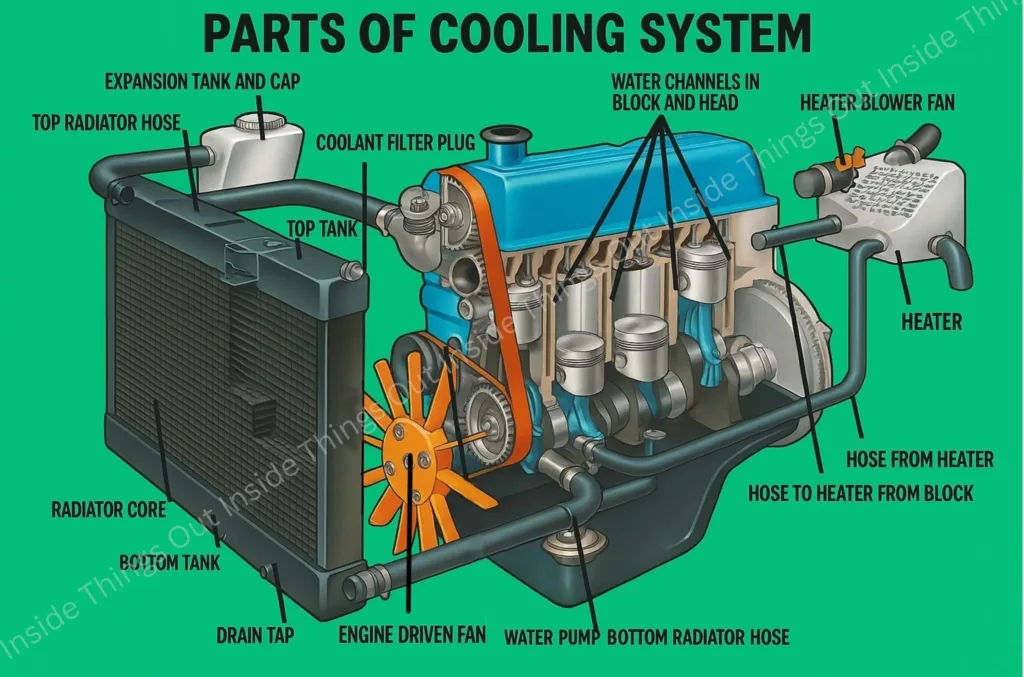

11. Cooling System

Combustion produces a lot of heat and with the absence of the cooling system the engine would overheat.

The most important features incorporate:

- Radiator- Dissipates heat in the air.

- Coolant- A combination of water, antifreeze that absorb the engine heat.

- Water pump- The water pump circulates coolant inside the engine.

- Thermostat- Keeps an engine at its optimum temperature.

Cooling system maintains the modern engine at the desired temperature so that it operates at this value in order to be efficient and do not pollute the environment.

12. Air Intake System

The system of air entry takes in a fresh air, cleans it, and sends it to the combustion chamber. Cleaner air makes combustion possible and thus internal engine components are not exposed to the debris.

Parts include:

- Air filter

- Throttle body

- Mass airflow sensor

Performance cars may use cold air intakes to deliver denser air for more power.

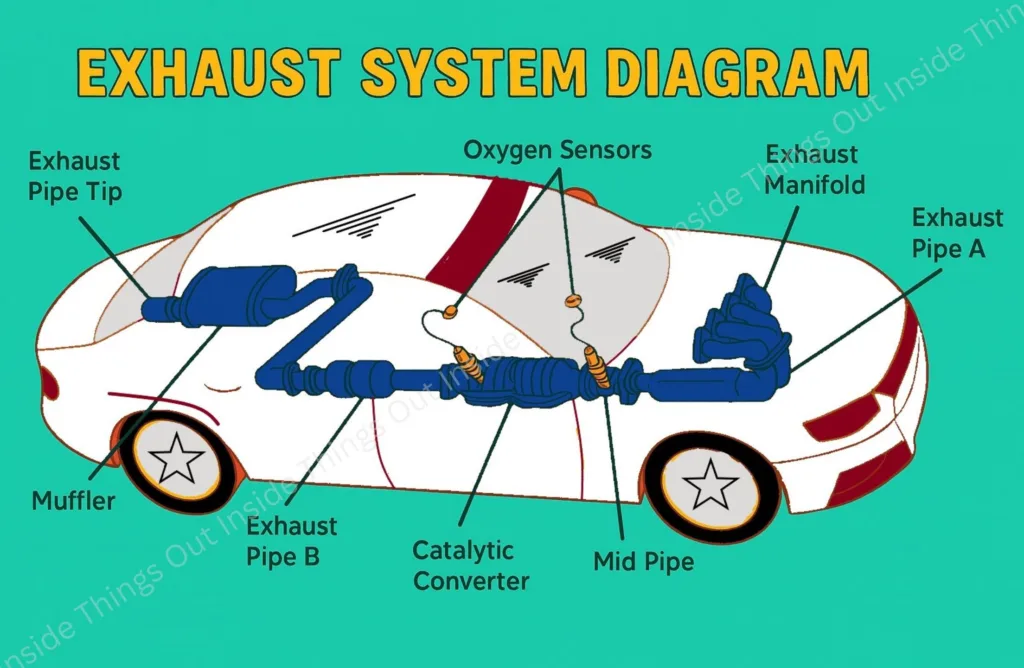

13. Exhaust System

The burnt gases are released to exhaust system.

It is comprised of:

- Exhaust manifold- This gathers the gases of two or more cylinders.

- Catalytic converter- This minimizes pollution emissions.

- Muffler- Acts as a silencer.

- Tailpipe- Allows gases into air.

New systems are designed in such a way that they minimize pollutants and abide by high emission standards.

14. ECU – Engine Control Unit

The Engine Control Unit (ECU) is digital engine brain. It gathers information from sensors (such as oxygen sensor, temperature sensors, and knocks sensors) and makes quick adjustments to things like fuel use, ignition timing, and airflow. If the ECU stops working properly, the car may have problems like slow acceleration, using too much fuel, or even engine failure. The ECU has several parts, including a tiny computer chip, circuit boards, and other electronic pieces. The chip runs special software that controls how the engine works. This software can be updated or changed to improve the car’s performance or fix any issues.

It is constantly evaluating performance, efficiency and emissions in the engine.

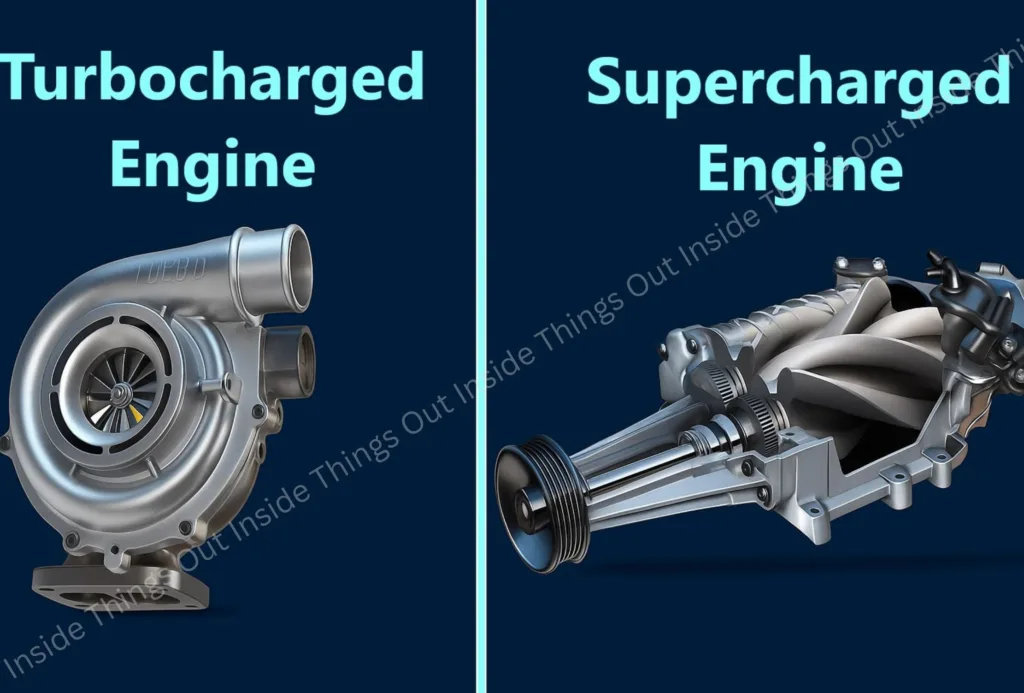

15. Turbocharger/Supercharger (Optional)

Others have turbocharger or even supercharger to enhance the power. These add more air to the combustion chamber hence generating more fuel and therefore power.

- Turbochargers spin a turbine using exhaust gases.

- The engine uses superchargers that are driven by the belt.

This type of equipment is, in particular, prevalent in performance and diesel engines.

Conclusion

Although an engine of a car can appear unique, it is actually a complex of different structurally carefully made parts which go in perfect harmony. Both the parts, namely the piston, valve, and the spark plug play an important role to convert fuel into motion. Being familiar with these engine parts does not only increase your sense of automotive technology, but also assists you in making proper maintenance choices.

By taking good care of it, e.g. changing the oil in time, servicing regularly and listening to warning signals, your engine can last you thousands of miles of stress free driving.